Micron Enterprises India

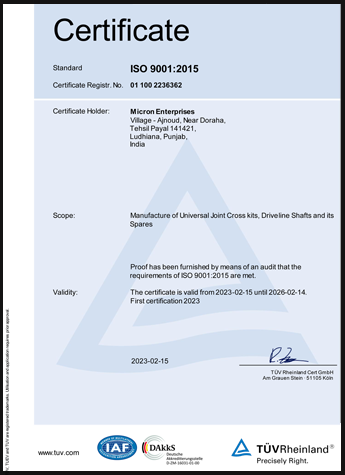

We are an IATF 16949:2009 Company, is a pioneer organization specializing

in manufacture and export of Universal Joint Crosses in India.

Years Of Experience

Bond Between Customers & Quality

Our Vision

To be global manufacturers and exporters of high quality automotive components across the world.

Our Mission

To make Micron Enterprises India one of the largest and technologically most advanced manufacturing company.

Micron Enterprises India

MICRON ENTERPRISES, an IATF 16949:2016 Company, is a pioneer organization specializing in manufacture and export of Universal Joint Crosses in India. Envisaging the vision to excel, we launched our operations in 1997. The company started in 1997 as a small scale manufacturing facility with Conventional machines and a covered area of 2000 sq.ft to produce 3000 Pcs U.J. Cross per month making a turnover of almost 45lac First Year.

Gradually it has modified into a high class manufacturing facility of 100000 sq. Ft. with a number of CNC Turning Centers, CNC SPM's along with a modern Heat Treatment and Metallurgical lab has reached a production of almost 200,000 Pcs U.J. Cross per month in the Year 2023-2024 taking the Turnover of the Company to $ 15.50 Million.

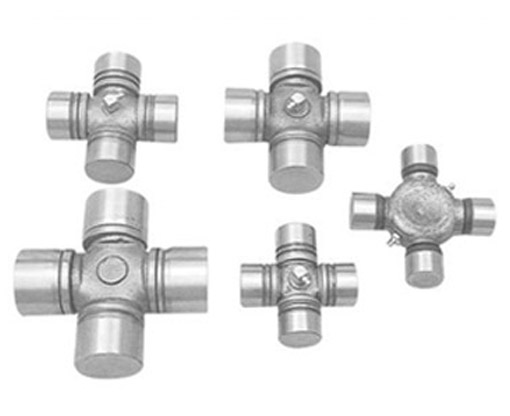

Our Products

Drive Shaft

Joint Part

U J Cross

U Joint

Questions, Wishes, Requirements, Information or Something else?

Quality Assurance

Quality products

To satisfy Customer by providing Timely delivery of Quality products. And company is committed to comply with requirements and continually improve the effectiveness of the quality management system.

Quality Measures

- Our workings are based on drawings. Drawings of every component is made before starting the mfg process. All process drawings are put on the machines so that operators and programmers do not make any mistake in mfg the parts.

- Machining is done on latest cnc turning centres,turn mill centres and cnc spms.

- Metallurgy plays a vital role in the mfg of universal joints. Heat treatment is done in a gas carburising furnace. We are checking surface hardness for 20% parts. further tests like Microstructure analysis, core hardness and effective case depth check on micro Vickers hardness tester are performed on one pc which we cut from every lot.

- Packing section is separate from the machining section.

Quality Instruments

- Instruments Available With Micron

- Digital & Dial Verniers

- Micrometers

- Height Gauges

- Compitator Stands

- Dial Gauges

- Bore Gauges